Id Grinding Mill Net 2877

ID Grinding TM Precision

ID Grinding Internal grinding is the primary process for the precision finishing of internal surfaces or bores The bores may be simple cylindrical surfaces or may be surfaces requiring the generation of complex and By 3D printing CBN grinding wheels, we can create custom precisionstructured superabrasives with unique surface slots, integrated cooling holes, passages and channels 3M™ Precision Structured Vitrified CBN Precision Abrasives for ID Grinding 3MBusiness Center Al Khuwair, Muscat, Sultanate of Oman +968 2447 9157 / 9925 2877 Fax: +968 2447 9158; ; hanoonllc@gmailId Grinding Mill Net 718restaurant fichtenhof Id id grinding mill net 2877 talleresgalvanbaezes2019年1月22日 Typically deployed at the end of manufacturing, these processes include methods of high precision internal grinding In this Specialized Methods of Internal Grinding Metal

.jpg)

en/117/id grinding mill net 3 7md at main dinglei2022/en

Host and manage packages Security Find and fix vulnerabilities2013年12月3日 The ID grinding quill is a shaft that’s housed within the grinding machine’s motor and supports and rotates the grinding abrasive wheels Because there are many different grinding machines with ID Grinding Quills: Styles, Materials, and 4 天之前 This is a guide to handheld grinding The information is mainly of a practical nature, intended for operators and oth ers professionally involved with these tools The Pocket Guide to Grinding Technique Atlas CopcoAt Nation Grinding, Inc, we are proud to offer topoftheline ID grinding services using our internal and eternal grinding machine that will improve the quality of your finished Id Grinding Mill Net 2877 outstyle

New Innovations in ID/OD Grinding Operations

2021年5月16日 The Voumard line of innovative, high productivity cylindrical ID/OD grinding machines has been designed for flexible internal/ external grinding operations and can process workpieces of almost every Precision Grindings is a leader in precision internal diameter grinding, commonly known as ID grinding A deep bench of highly trained machinists with decades of experience and the most sophisticated ID grinding Internal Grinding Precision GrindingsOur internal diameter (ID) grinding service utilizes conventional or CNC ID grinders using diamond or CBN grinding wheels to grind your carbide or harden tool steel parts up to 25” OD and ID’s starting at 0200 We can accommodate lengths up to 10”, weighing up to 1,000 lbs Contact our sales department to discuss your requirementsID Grinding Glen CarbideYou've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activitysbm/sbm id grinding mill net 3068md at master sbm

CNC Internal Grinding (ID Grinding) Midway Grinding, Inc

Cylindrical ID grinding, also known as Internal Grinding, is a machining process used to remove material from the inside of a cylinder or conical workpiece and give it new internal dimension At Midway Grinding Inc, our expert machinist specializes in cylindrical ID grinding services to unmatched by our competitors2024年8月29日 1234 West 78 th Street Cleveland, Ohio 441021914 PHONE 8883393006 Fax 2166315264 info@universalgrindingExploring ID OD Grinding in Modern ManufacturingUsually, this tends to be a longer process than OD grinding as the ID grinding stone is smaller and requires the operator to make smaller cuts to ensure that the ID grind is perfect and to the correct size We have 7 ID grinders which we can grind from 500 up to 12” internal diameter, 6 through feed and plunge centerless grinders that can ID GRINDING R S Grinding2019年1月22日 In ID grinding and ID honing, high precision internal grinding involves some of the most challenging abrasive finishing techniques The right manufacturing partner will work with you to understand your part requirements and help you determine if ID honing or grinding is appropriate for your application — or if one of many other available Specialized Methods of Internal Grinding Metal Cutting

.jpg)

OD ID Grinding Services

6 天之前 ID grinding services, also known as internal diameter grinding, is a meticulous process where the stock is removed from the inside of a workpiece Raymac Grinding offers hightolerance internal diameter grinding for ferrous, nonferrous and many other materials Raymac Grinding is capable of removing stock from even the most complicated workpiecesThe KELLENBERGER 1000 universal CNC OD/ID grinding machine represents the ultimate expression of the Swiss ethos: a technical tourdeforce encompassing every facet that has come to define KELLENBERGER, a premium Hardinge brand, as the world leader in grinding design, precision, and quality KELLENBERGER 1000’s clean, sleek, and KELLENBERGER® 1000 Hardinge AsiaAs grinding media gradually depletes in the ball mill, so does the power draw Deviation for a set point then activates the machine to dispense grinding media into the weigh hopper, where it is reordered prior to a pneumatic gate opening and allowing it to discharge in the feed hopper to compensate for the weight of balls required to restore Grinding Mills – MechProTech MPT2023年11月7日 grindgrind the action of grinding something into a smaller pieces mill a building where they grind flour or other grains OR can mean to grind "we grind the flour at the mill" "we milled wheat into flour" 的同义词"grind" 和 "mill " 和有什么不一样? HiNative

ID Grinding Services Interior Diameter Grinding

ID grinding is available for parts up to 30 inches in diameter and 24 inches in depth Duval can size and finish parts up to tolerances of +/–00001, ensuring your part functions as designed Maximum Diameter: 30 inches; 2013年12月3日 Selecting the proper wheel quill is critical to a successful ID grind operation To further understand ID grinding quills, it’s necessary to know the different materials used in manufacturing ID grinding quills and ID Grinding Quills: Styles, Materials, and CNC ID GRINDING CAPABILITIES Internal grinding is a precision process used to remove material from an internal, and in many cases, external features with highly accurate results Internal Grinding is the most difficult grinding process in the industry and requires the most advanced machines and highly trained personnel Grind All has the Internal Grinding Grind All Inc2015年11月20日 The grinding quill is threaded into the grinding wheel spindle and is what holds the grinding wheel A highly rigid ID grinding machine with high precision ID grinding wheel spindles requires a rigid and precise grinding quill What to Look for in a Grinding Quill Below are some items to consider when selecting the correct grinding quill:ID Grinding: Success Starts With the Quill Canadian

New Innovations in ID/OD Grinding Operations Hardinge

2020年3月24日 With ID grinding, small amounts of material are removed from a part to finish off its inner surface Just as with OD grinding, the ID grinding wheel and the object rotate in opposite directions, giving reversed directional contact of the two surfaces where the grinding occurs However, although single purpose OD or ID machines are still sold The Bryant and Landis line consists of dedicated ID and OD grinders for high precision and production, as well as combination ID/OD grinders for OD, ID, raceway, and face grinding These grinders are suitable for various applications and are available in different sizesID/OD grinding machines for small components Fives GroupUnited Grinding, Inc provides precision, ID, OD and surface grinding services on small to extremely large parts, up to 70" in diameter and 40" tall top of page United Grinding, Inc We specialize in inside, outside cylindrical and surface precision grinding What makes us unique is we can hold close tolerances to within 0001 inches AND we ID Grinding Services Interior Diameter Grinding Services2024年2月12日 Factor Description; Type of Mill: Manual: Requires handcranking, laborintensive, no power consumption Electric: Uses a motor, more convenient, faster grinding: Grinding Mechanism: Stone Grinding: Produces even, finetextured flour, ideal for bread making Impact Grinding: Fastmoving metal fins break grains into flour, quicker but How to pick the best home grain mill: A buyer's guide for

Norton IDealPrime Grinding Wheels Optimize ID Grinding Performance

2022年2月22日 There are numerous challenges associated with ID grinding that can result in poor surface finish, excessive friction and heat buildup or excessive grinding tool wear Lack of Rigidity One of the most important factors in ID grinding concerns the rigidity of the shaft or arbor — commonly called the quill — which holds the grinding wheelA starter list of questions would include: Do you need lab grinding mills or production sized mills?Do you need to perform wet or dry milling?Do Skip to content 3309293333 Mixing Tanks; Other Products Services Lab Testing Services; Particle Characterization; Toll Milling/Grinding; Spare Parts and Refurbishing;Selection Tips for Grinding Mills Union Process2024年9月3日 With over 50 years of experience, we’ll design a custom ID grinding quill for your production bore grinding application that provides you with the lowest cost per part possible We can provide precision ground Internal Grinding Quills Fischer Special ToolingGrinding mill is an industrial grinding mill used to grind solid stones into fine powder Stable performance, high efficiency and low consumption, easy use +17 [ protected] language >Shibang Industry Grinding MillIndustrial Grinding Mill, Ultrafine

Laboratory Ultra Centrifugal Mill ZM 300 RETSCH

"The Retsch Ultra centrifugal mill is the one “grinder” that gave us the particle size and hence the best analytical result (eg oil content) in a variety of oilseed sample types Over 30 years in the laboratory, allows me to call the Retsch mills/ grinders as the “gold standard” when it comes to sample preparation" Douglas DeClercq DRDBetween 2021 and 2022 the exports of Balls, iron/steel, forged/stamped for grinding mills grew by 259%, from $133B to $167B Trade in Balls, iron/steel, forged/stamped for grinding mills represent 00071% of total world trade Balls, iron/steel, forged/stamped for grinding mills are a part of Other Iron ProductsBalls, iron/steel, forged/stamped for grinding millsBall mills are furthermore characterized by significant differences in the sizes of available grinding jars Retsch offers mills with jar capacities from 15 ml up to 150 l and balls are available from 01 mm to 40 mm, see Figure 2 Retsch displays the strength and efficiency of each ball mill model in a spidernet diagram, see Figure 3Ball Mills Suitable for every application Retsch2019年11月13日 mill 、 grit 、grind的磨,有什么区别?你好。希望以下的解答能为你解惑。三个词你查字典都有磨的意思,但有区别。【mill】:碾磨。特别是磨成粉状都用这个词。【grit】: 这个词做 磨 讲,一般只用在 咬牙切齿 上,mill 、 grit 、grind的磨,有什么区别? 百度知道

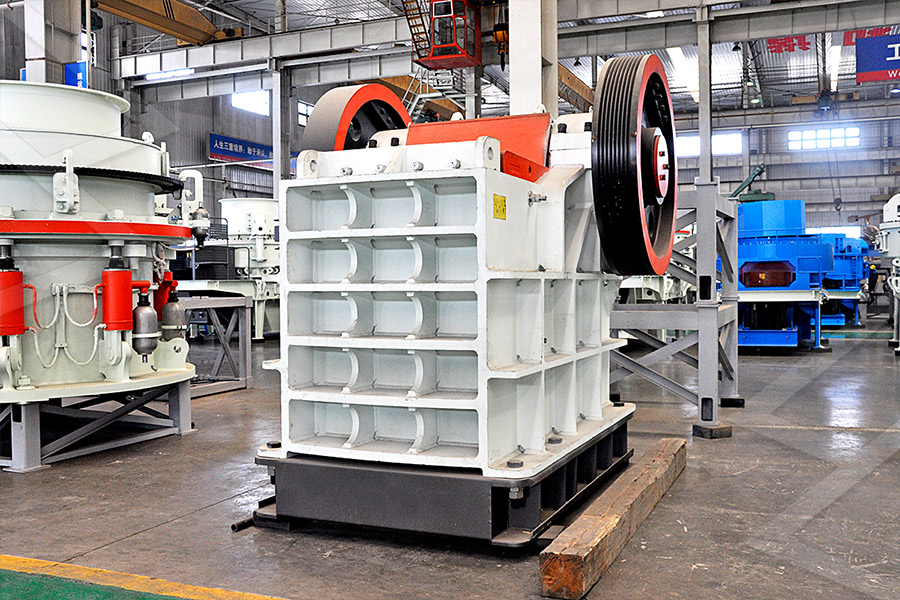

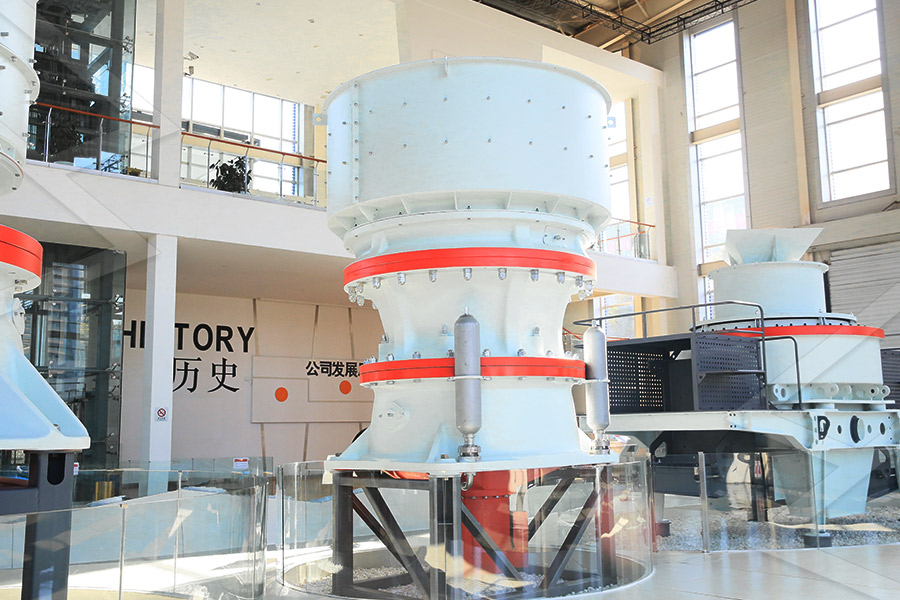

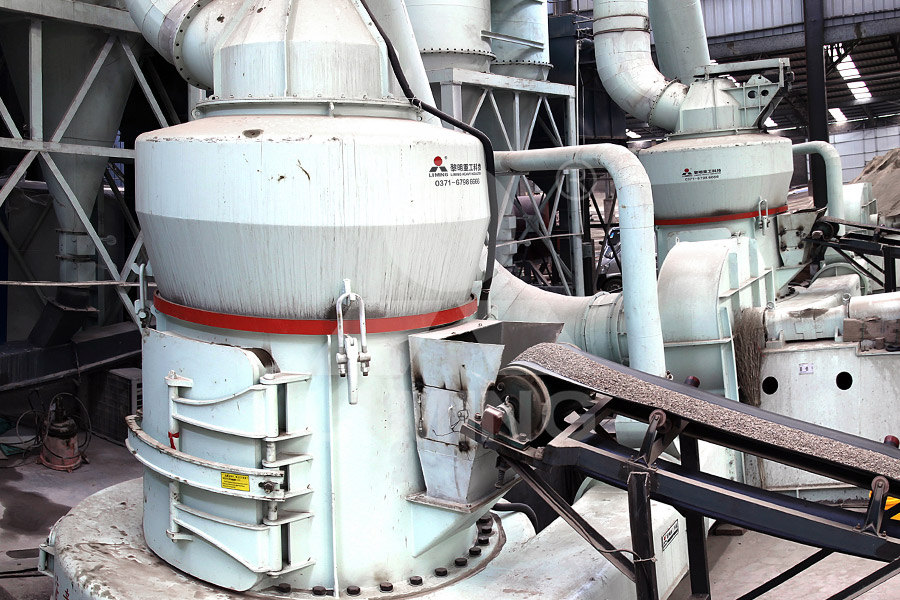

How it Works: Crushers, Grinding Mills and Pulverizers

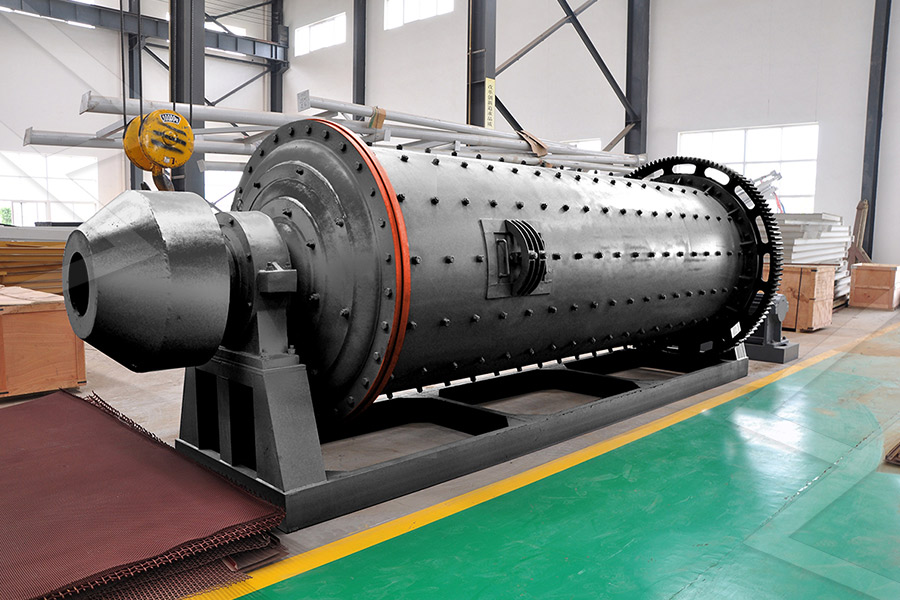

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap ID Grinding or Internal Diameter Grinding is used when multiple diameters, faces and/or forms need ground Concentricity or squareness requirements can be achieved with precision chucks Blind hole and length applications can easily be accommodated Special Super Abrasives are utilized for difficult materialsID Grinding1 天前 Browse WigLBug Grinding Mill in the International Crystal Laboratories catalog including Item #,Item Name,Vial Capacity,List Price 9734788944 iclmail@internationalcrystal CloseWigLBug Grinding Mill International Crystal LaboratoriesBall mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities Understanding their working principle, different types, parts, applications, advantages, and recent developments helps to appreciate their significance and wideranging applications in industries such as cement Ball Mill Grinding Machines: Working Principle, Types, Parts

.jpg)

What is Inner Diameter Grinding? Grindmasters

04/13/2024 Inner diameter grinding (ID grinding), or bore grinding, is the meticulous process of removing material from the inside diameter of a workpieceInternal grinding is the primary process for the precision finishing of internal surfaces or bores The bores may be simple cylindrical surfaces or may be surfaces requiring the generation of complex and exact profiles for ID Grinding TM Precision2013年12月13日 For boregrinding operations with oscillation, it is generally a good idea to design the quill long enough to be able to push at least ½ of the wheel thru the bottom of the bore you are grinding Also, when moving to the deepest position, you need to consider how much room is required at the nose of the spindle for peripherals like coolant All About Grinding Quills The Meister ToolboxGrinding Mills Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 71 Introduction Grinding is the last stage in the comminution process where particles are reduced in size by a combination of impact and abrasion, either dry, or more commonly, in suspension in waterGrinding Mill an overview ScienceDirect Topics

Precision Abrasives for ID Grinding 3M

When exploring a new abrasive wheel for ID grinding, it’s important to understand your current and potential grinding performance The specific material removal rate, also known under the abbreviation Q’w, indicates how many mm 3 are removed per second with a 1 mmwide wheel This value allows for a direct comparison between different grinding any of various machines for grinding (as of grain or sugarcane) or for dressing by grinding (as of metal parts); a lapidary's lathe See the full definition Menu ToggleGrinding mill Definition Meaning MerriamWebsterOur main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Home; About Us; Products Grinding Mill;SBM Ultrafine Powder Technology Industrial Grinding Mill, American Precision Services’s OD/ID and surface grinding services are capable of meeting the most precision tolerances and exacting finish requirements for parts such as shafts, sleeves, wear plates, and bearing housings Our large, wellmaintained facility has the capacity to OD/ID grind parts with dimensions of up to 20” in diameter and 10’ in length ID, OD, Surface Grinding American Precision Services, Inc

Turning, Milling, Grinding, EDM Design Build Moeller

Our grinding capabilities include CNC ID/OD grinding, creep feed grinding, and superabrasive 5axis CBN (cubic boron nitride) grinding We would stack two sine plates bolted together on a Bridgeport to mill a compound angle and handgrind the radius callouts on our own endmills As Moeller grew and evolved, we built on that foundation and Precision Grindings is a leader in precision internal diameter grinding, commonly known as ID grinding A deep bench of highly trained machinists with decades of experience and the most sophisticated ID grinding Internal Grinding Precision GrindingsOur internal diameter (ID) grinding service utilizes conventional or CNC ID grinders using diamond or CBN grinding wheels to grind your carbide or harden tool steel parts up to 25” OD and ID’s starting at 0200 We can accommodate lengths up to 10”, weighing up to 1,000 lbs Contact our sales department to discuss your requirementsID Grinding Glen CarbideYou've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activitysbm/sbm id grinding mill net 3068md at master sbm

.jpg)

CNC Internal Grinding (ID Grinding) Midway Grinding, Inc

Cylindrical ID grinding, also known as Internal Grinding, is a machining process used to remove material from the inside of a cylinder or conical workpiece and give it new internal dimension At Midway Grinding Inc, our expert machinist specializes in cylindrical ID grinding services to unmatched by our competitors2024年8月29日 1234 West 78 th Street Cleveland, Ohio 441021914 PHONE 8883393006 Fax 2166315264 info@universalgrindingExploring ID OD Grinding in Modern ManufacturingUsually, this tends to be a longer process than OD grinding as the ID grinding stone is smaller and requires the operator to make smaller cuts to ensure that the ID grind is perfect and to the correct size We have 7 ID grinders which we can grind from 500 up to 12” internal diameter, 6 through feed and plunge centerless grinders that can ID GRINDING R S Grinding2019年1月22日 In ID grinding and ID honing, high precision internal grinding involves some of the most challenging abrasive finishing techniques The right manufacturing partner will work with you to understand your part requirements and help you determine if ID honing or grinding is appropriate for your application — or if one of many other available Specialized Methods of Internal Grinding Metal Cutting

OD ID Grinding Services

6 天之前 ID grinding services, also known as internal diameter grinding, is a meticulous process where the stock is removed from the inside of a workpiece Raymac Grinding offers hightolerance internal diameter grinding for ferrous, nonferrous and many other materials Raymac Grinding is capable of removing stock from even the most complicated workpiecesThe KELLENBERGER 1000 universal CNC OD/ID grinding machine represents the ultimate expression of the Swiss ethos: a technical tourdeforce encompassing every facet that has come to define KELLENBERGER, a premium Hardinge brand, as the world leader in grinding design, precision, and quality KELLENBERGER 1000’s clean, sleek, and KELLENBERGER® 1000 Hardinge AsiaAs grinding media gradually depletes in the ball mill, so does the power draw Deviation for a set point then activates the machine to dispense grinding media into the weigh hopper, where it is reordered prior to a pneumatic gate opening and allowing it to discharge in the feed hopper to compensate for the weight of balls required to restore Grinding Mills – MechProTech MPT