How A Iron Ore Crushing And Screening Works

Iron Ore Processing: From Extraction to

2024年4月26日 Crushing and screening are integral processes in iron ore processing that help prepare the mined ore for further beneficiation and downstream use These processes involve breaking down the mined ore 2023年12月1日 In this study, the DEM (Discrete element method) bonded particle model is constructed to simulate the crushing process of iron ore based on the Apollonian sphere Crushing characteristics and performance evaluation of iron ore 2023年6月3日 Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the MeasurementControl for Crushing and Screening ProcessSix steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine The six main steps of iron ore processing

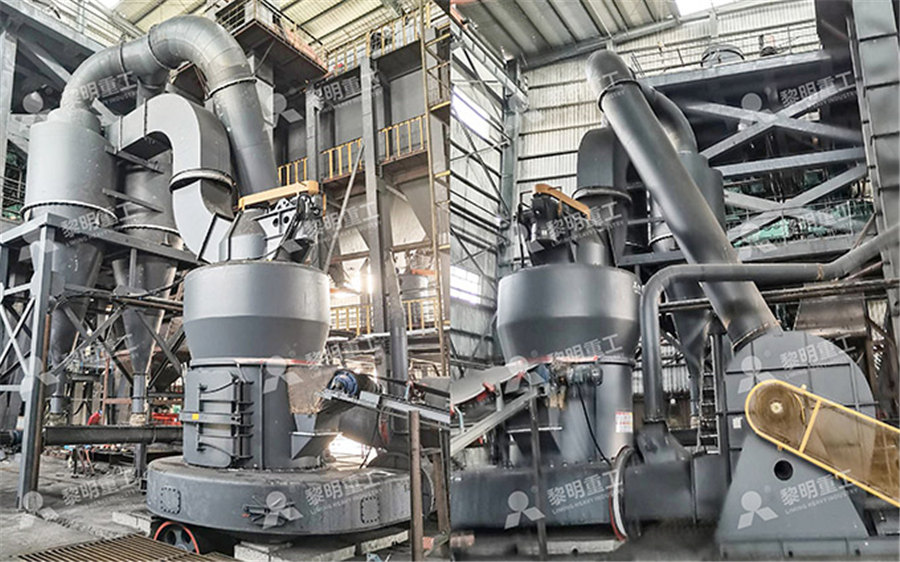

MeasurementControl for Crushing and Screening

2023年6月2日 Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the The journey of iron ore from extraction to readyforprocessing involves a series of meticulous steps—crushing, screening, grinding, separating, and agglomerating Each How is iron ore crushed ready for processing?2021年6月25日 The crushing process generally includes crushing, prescreening and inspection screening steps, and if necessary, it also includes ore washing or predressing operations A crushing operation and a Common Iron Ore Crushing and Screening 2024年1月16日 The iron ore screening process plays a pivotal role in determining the dimensions of pellets that enter the firing process of a pelletizing plant The particle size The impact of new technologies on the iron ore screening

.jpg)

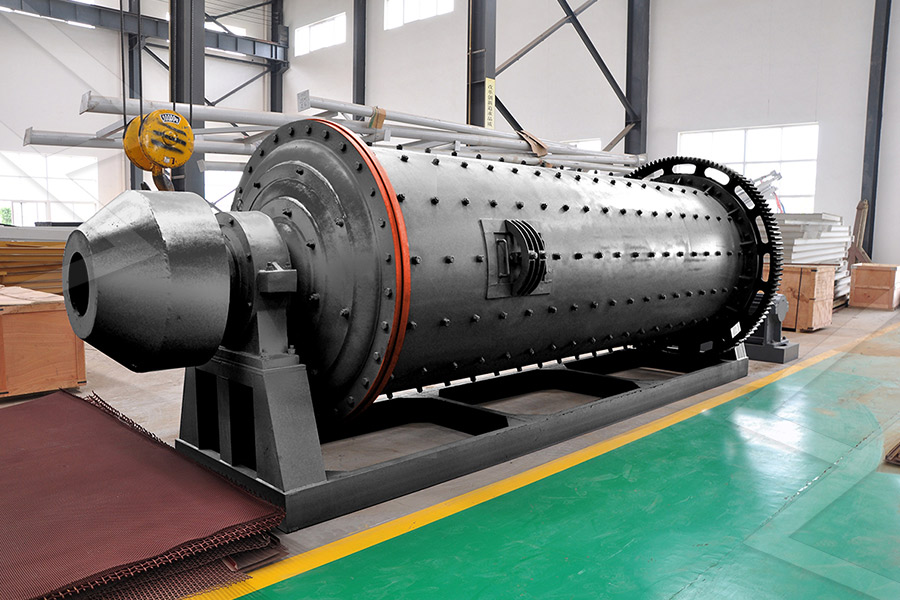

Comminution and classification technologies of iron ore

2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for 2022年8月3日 In the iron ore crushing process, the feeder, first crushing, secondary crushing, screening, fine crushing and dry selection are generally used For the sake of economy, generally the finer the ore particle size Iron ore crushing and screening process 2020年11月21日 The system has been implemented in an iron ore crushing and screening plant in India, and its efficacy has been evaluated for controlling dust emission The measured PM 10 concentration at six monitoring sites in the work zone of crushing and screening plant varied from 1202 to 1540 μg m −3 with an average value of 1394 μg m Intelligent dry fog dust suppression system: an efficient2021年6月25日 The processing sequence consisting of crusher and screening machine is called the crushing and screening process The crushing process generally includes crushing, prescreening and Common Iron Ore Crushing and Screening Process

.jpg)

Crushing Services and Material Supply – Iron

1 天前 Iron Mine Contracting offer a range of crushing, screening and material rehandle options at production rates up to 1500tph We own and operate a fleet of track mounted plant for rapid mobilisation and 2023年7月22日 Ore crushing is the process of breaking, splitting, extrusion, impacting, and grinding of large solid ore with external force to reduce the particle size of large ore materials which is called inspection and screening Therefore, the crusher often works with the screen to form a closedcircuit system (as shown in the third section of Fig Ore Crushing SpringerLinkThere is now a new generation of mobile crushing and screening plant systems available which have been developed based on the motivation of reducing truck haulage Newly designed mobile crushing and screening plant systems have the advantages of mobility, flexibility, economy and reliable performance, making this system very appealing for Mobile Crushing and Screening Plant Applications for Small2017年3月3日 Particle impact noise detection (PIND) test is a kind of reliability screening technique which is used to detect free particle in hermetical components and is specified in MILSTD883E method 20207(PDF) ORE SEPARATION BY SCREENING ResearchGate

Mine Crushing Auscrush

Mine Crushing At AusCrush Recycle Pty Ltd, we are experienced in mine site crushing and screening works, with particular expertise in the processing of Iron Ore (both Magnetite and Hematite variants) and other similar products Whether you require a lump and fines or all fines product, we are able to offer tailored services to []2024年1月1日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as MeasurementControl for Crushing and Screening Process2024年6月13日 The processing and production technology of copper ore mainly includes three processes: crushing, grinding, and beneficiationThe modern copper ore crushing method adopts threestage closedcircuit crushing, which can not only complete the crushing and partial dissociation of the ore, but also improve the efficiency of subsequent Copper Introduction And Ore Crushing JXSC Mineral2023年12月1日 1 Introduction Due to the decreasing reserves of highgrade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al, 2014)The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to Crushing characteristics and performance evaluation of iron ore

.jpg)

Cost Analysis for Crushing and Screening Part II CORE

2021年8月13日 different/multiple crushed products within a designed crushing circuit 13 Purpose and Goals The purpose of this master thesis will be further development of the Cost Analysis for Crushing and Screening Model The base of this project will be Cost Analysis for Crushing and screening – Part I2024年2月2日 A usCrush first commenced crushing and screening iron ore at Peak Iron Mines’ Peculiar Knob operation in South Australia in November 2021 And the mobile crushing and screening services provider Crushing it Australian Mining5 天之前 BE international boasts extensive experience in crushing and processing ore mineralogies including gold, iron ore, manganese, detrital, chrome, quartz, nickel, kimberlite, and coal to name a few Our vast crushing equipment fleet is available at a moment's notice and is convenient for shortterm interventions typically required during planned Sustainable efficient crushing and screening services BE of high phosphorus iron ore by mechanical crushing and screening methods were investigated in the present work The reduction behavior of high phosphorus iron ore by carbonaceous materials was evaluated as a function of reduction temperature, reduction time and carbon mixing ratio Most of the phosphorus comDephosphorization Treatment of High Phosphorus Iron

.jpg)

Advances in screening technology in the mining sector

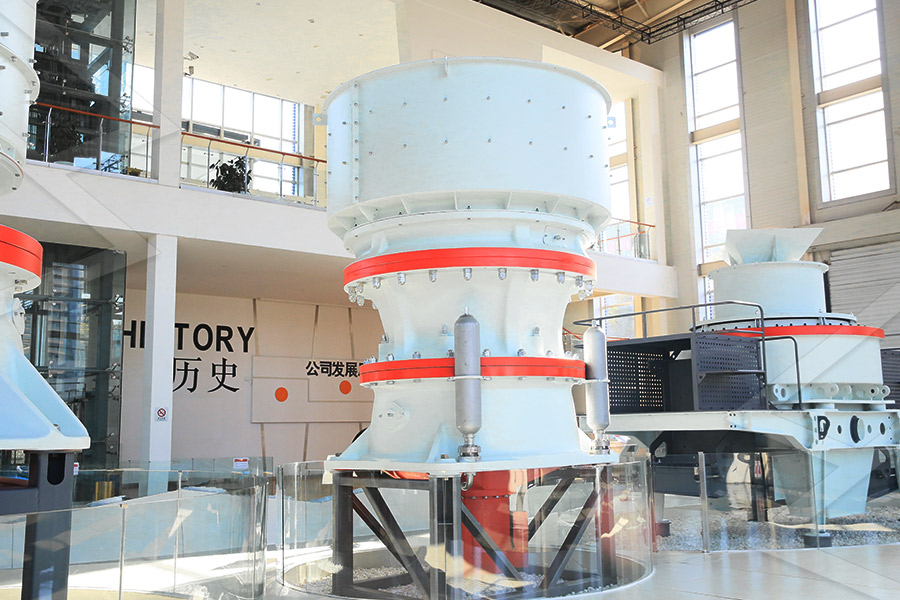

3 Screening machines for iron ore and coal The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined While good quality magnetite is now dryprocessed, hematite from deposits below the water line requires wet processing due to sticky quartz and clay contaminations2024年9月2日 Our team of factorytrained fitters, welders and mechanics can turn your original investment back into a new machine Striker will offer a full warranty on all machines it refurbishes in the factory “We recently brought a mobile jaw crusher back into our Henderson factory, this machine had been working on Iron Ore for the past 30,000 Crushing and Screening Services and Support Striker Crushing2021年3月18日 #2 Screening The screening operation can screen gold ore according to the particle size, increase the production capacity of grinding and improve the work efficiency of grinding, and at the same time avoid overcrushing Screening operations can be divided into prescreening and inspection screeningHow Does A CIP Gold Processing Plant Work? Miningpedia2022年1月20日 "There are two ways of looking at it: there's screening prior to crushing, and then screening after crushing We want to make sure that we've got the whole process balanced Smith recalled a visit to an iron ore operation in Western Australia that was having trouble with a doubledeck banana screen with a capacity of 3,000 tonnes per hourThe screening process: a vital component of the crushing

.jpg)

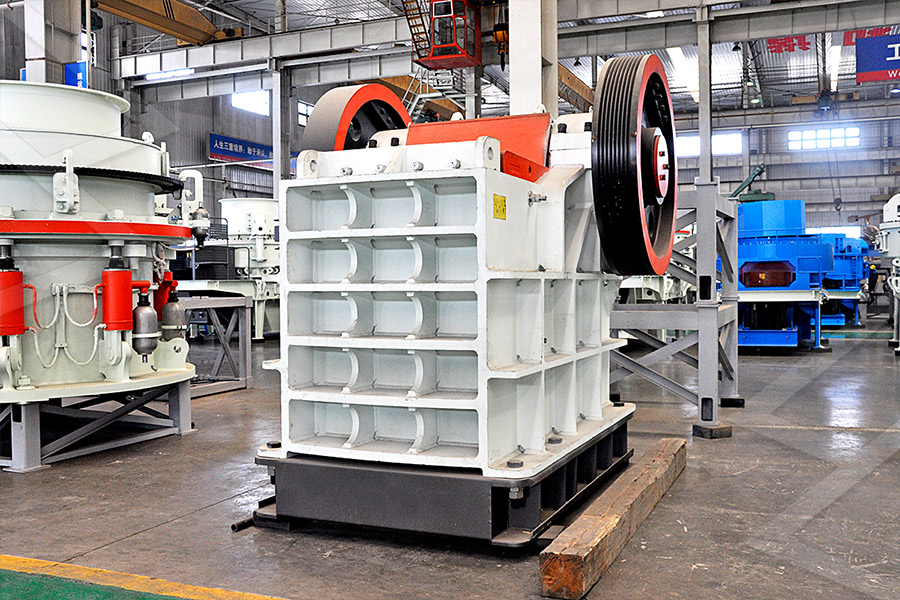

Iron Ore Crushing and Screening winnermanufacturing

2024年8月21日 The jaw crusher make the first step crushing work and then through the conveyor, the crushed Iron ore will be put into the multicylinder hydraulic cone crusher for the second step crushing After round sieve screening, broken material of unqualified materials will be sent back to cylinders hydraulic cone crusher while the qualified 2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 11 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021)As shown in Fig 13, China is the largest iron ore Introduction: Overview of the global iron ore industry6 天之前 According to Ashoktaru Chattopadhyay, Vice President, Sandvik Crushing Screening Business India, the demand projection in the near future looks promising, especially for the road segment The iron ore Crushing Screening Market Seeing Renewed 2024年8月20日 The majority of steel production is supported by iron ore sourced from high grade hematite deposits, although a significant fraction comes from the magnetite deposits Compared to directMagnetite Iron Ore Design Case Study ResearchGate

.jpg)

CRUSHING PLANT PROCESS OPTIMISATION AusIMM

2024年8月29日 Crushing and screening processes design is a complex and multi disciplinary task A process can be confi gured in many ways in order to fulfi l the same task The question then quickly arise: What is Earlier work by the author has focused on optimisation on existing plants (Svedensten, 2007)2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODS%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources2023年6月2日 Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the continuous, stable, and safe operation of ore crushing and screening In the practice of production, the crushing and screening process is related to the particle size of raw ore, MeasurementControl for Crushing and Screening

.jpg)

(PDF) Crushing and Screening Handbook Academia

Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainabilityEven though the ore is reduced below 3 mm with conical and some impact crushers, this process is called crushing The process of size reduction is defined by below conversion formula: The ore whose size will be reduced + Energy = Reducedsize ore + Sound + HeatWHAT IS THE CRUSHING PROCESS? MEKA2021年6月24日 detailed responses of that ore to specific physical and chemical upgrading procedures It forms the basis of metallurgical process design or process modifications Techniques used in ore characterisation include: x crushing, grinding and screening tests with associated assaying and mineralogy to determine breakage (work index) and METALLURGICAL TESTING METHODS (RENISON, Our fleet of mobile crushing and screening units provides you with onsite crushing and screening solutions, bringing the equipment directly to your project location Additionally, we also offer mobile crushers for hire, Seneca Crushing and Screening Equipment

Crushing and Screening Services VanCon Enterprises

VanCon provides crushing and screening services for industrial bulk materials throughout the BC interior, meeting your specific needs at a competitive price Why Work With Us; Jobs – Apply Now! including aggregates, iron ore, coal and coke, steel and blast furnace slag, and recyclables such as broken concrete and asphalt and soils 2021年12月2日 Roy Hill Chief Operating Officer, Anthony Kirke, said: “CSI has been a valued partner to Roy Hill since February 2017, initially providing crushing services, followed by the addition of screening and associated haulage services for our Direct Shipped Ore CSI’s agility in responding to changing operational requirements, commitment to CSI to deploy 'innovative' screening solution at Roy Hill iron ore 2016年7月12日 Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers Crushing is done underground at a few large mines In general, the jaw crusher is the most suitable primary machine, yet many Crushing Screening Plant 911 Metallurgist2011年2月17日 The dephosphorization treatment of the prereduced iron ore by mechanical crushing and screening methods was evaluated as a function of the initial reduction condition, screen size, and the Dephosphorization Treatment of High Phosphorus Iron Ore

Home Auscrush

From mine and quarry crushing to site civil works, you can rely on our fully trained, experienced, and competent operators for solutions Our scope of work is broad, including; Load and haul campaigns; AusCrush commenced crushing and screening Iron Ore in November 2021 This campaign is situated 90 kilometres Southeast of Cooper Pedy 2015年12月31日 Mining starts with the drilling and blasting processes followed by the excavation of unprocessed ore and its loading on haul trucks, transporting it to the crushing, screening, and separation Life cycle assessment of iron ore mining and processing2024年8月12日 Keywords: Crushing, Mass balance control, Limiting control, Dynamic modeling, Sensor fusion 1 Introduction Crushing is an essential multistage processing step in the production of minerals, metals, aggregates, and cement A crushing circuit comprises a combination of unit operations for crushing, screening, conveying, feeding, and Mass balance control of crushing circuits Tampereen 2022年12月28日 Prescreening is the process of screening out the material with a qualifying particle size before crushing operations are carried out This process is designed to avoid overcrushing of the material and to improve screening efficiency and reduce power consumption Check screening is the process of sieving out the material after it has been Mineral Screening: The Complete Guide Miningpedia

.jpg)

Intelligent dry fog dust suppression system: an efficient

2020年11月21日 The system has been implemented in an iron ore crushing and screening plant in India, and its efficacy has been evaluated for controlling dust emission The measured PM 10 concentration at six monitoring sites in the work zone of crushing and screening plant varied from 1202 to 1540 μg m −3 with an average value of 1394 μg m 2021年6月25日 The processing sequence consisting of crusher and screening machine is called the crushing and screening process The crushing process generally includes crushing, prescreening and Common Iron Ore Crushing and Screening Process1 天前 Iron Mine Contracting offer a range of crushing, screening and material rehandle options at production rates up to 1500tph We own and operate a fleet of track mounted plant for rapid mobilisation and Crushing Services and Material Supply – Iron 2023年7月22日 Ore crushing is the process of breaking, splitting, extrusion, impacting, and grinding of large solid ore with external force to reduce the particle size of large ore materials which is called inspection and screening Therefore, the crusher often works with the screen to form a closedcircuit system (as shown in the third section of Fig Ore Crushing SpringerLink

.jpg)

Mobile Crushing and Screening Plant Applications for Small

There is now a new generation of mobile crushing and screening plant systems available which have been developed based on the motivation of reducing truck haulage Newly designed mobile crushing and screening plant systems have the advantages of mobility, flexibility, economy and reliable performance, making this system very appealing for 2017年3月3日 Particle impact noise detection (PIND) test is a kind of reliability screening technique which is used to detect free particle in hermetical components and is specified in MILSTD883E method 20207(PDF) ORE SEPARATION BY SCREENING ResearchGateMine Crushing At AusCrush Recycle Pty Ltd, we are experienced in mine site crushing and screening works, with particular expertise in the processing of Iron Ore (both Magnetite and Hematite variants) and other similar products Whether you require a lump and fines or all fines product, we are able to offer tailored services to []Mine Crushing Auscrush2024年1月1日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as MeasurementControl for Crushing and Screening Process

.jpg)

Copper Introduction And Ore Crushing JXSC Mineral

2024年6月13日 The processing and production technology of copper ore mainly includes three processes: crushing, grinding, and beneficiationThe modern copper ore crushing method adopts threestage closedcircuit crushing, which can not only complete the crushing and partial dissociation of the ore, but also improve the efficiency of subsequent 2023年12月1日 1 Introduction Due to the decreasing reserves of highgrade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al, 2014)The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to Crushing characteristics and performance evaluation of iron ore