Jaw Crusher Tutorial

Jaw Crusher Basics in 3 Minutes china

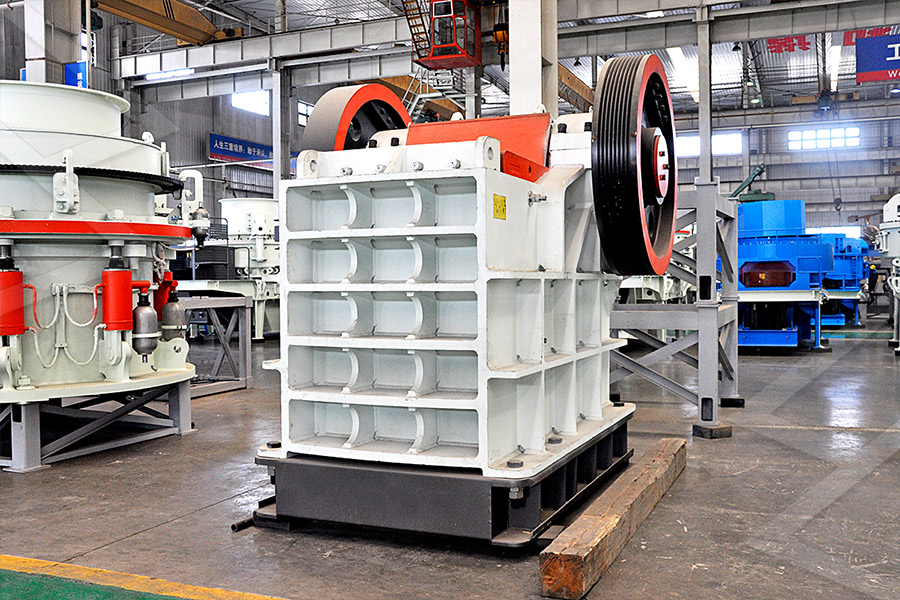

3 天之前 The jaw crusher works by using a moving jaw and a fixed jaw to crush and grind the rocks The material is fed into the jaw crusher by a vibrating feeder, and then it is This video shows the analysis of the jaw crushing process for different materials (iron ore, limestone and granulite) The Tavares Breakage model in EDEM allows accurate EDEM simulation of Jaw Crusher2024年2月18日 Let’s delve into the jaw crusher diagram—a revealing illustration showcasing the trajectory of the movable jaw plate In action, this plate swings on the eccentric shaft, applying a forceful compression to Jaw Crusher Diagram: Simplified Guide JXSC2024年2月5日 A jaw crusher is a robust, essential and rugged crusher used primarily in mining and construction for the initial crushing of large rocks and ore Positioned at the start of the crushing process, it uses How Does a Jaw Crusher Work? A Simple Guide

.jpg)

The Ultimate Guide to Jaw Crushing Machines:

2023年2月21日 A jaw crushing machine is a type of equipment used to break down hard materials, such as rocks, minerals, and ores It consists of a fixed jaw plate and a movable jaw plate that is positioned in a V Introduction to coal sampling Wes B Membrey, in The Coal Handbook (Second Edition), 2023 4511 Jaw crushers Jaw crushers are comprised of a fixed plate and a moving Jaw Crusher an overview ScienceDirect Topics5 天之前 First, you will need to carefully select the jaw plates so that they can effectively crush your chosen material Second, you should ensure that the jaw plates fit snugly into the crusher’s jaw Third, you will need to set Jaw Crusher: What Is It How Does It Work?2023年6月21日 Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable The movable jaw plate approaches the fixed jaw plate Jaw Crusher SpringerLink

.jpg)

jaw crusher 百度百科

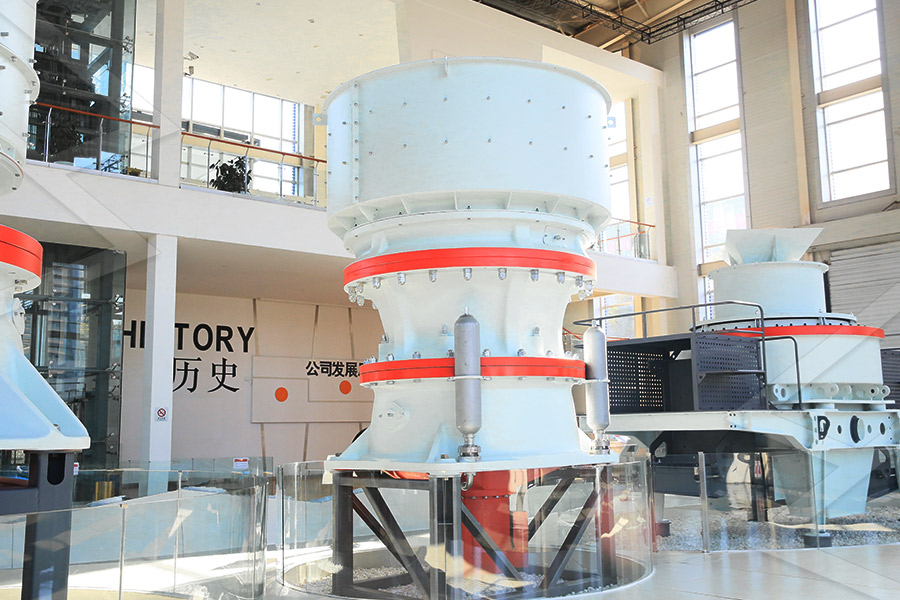

It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is under 200Mpa, that is, suitable for primary crush 2021年5月14日 Jaw crusher is the commonly used crushing equipment in mining This article will introduce what operations should be done before starting the jaw crusher, How to Operate the Jaw Crusher Correctly? miningpedia2024年4月6日 Types of Jaw Crushers: There are two types of Jaw Crushers: Single Toggle and Double Toggle Single Toggle: The single toggle movement jaw crusher, more compact than double toggle The Ultimate Guide to Jaw Crushers PuzzolanaThe 4000 is a 400mm x 170mm jaw action crusher Instant hydraulic adjustable jaws allow output product sizes to range from 20mm up to 80mm Dust suppression is fitted as standard, by means of fine water spray RR 4000 Red Rhino Crushers

.jpg)

CHPL332 Size Reduction of Solids Tutorial

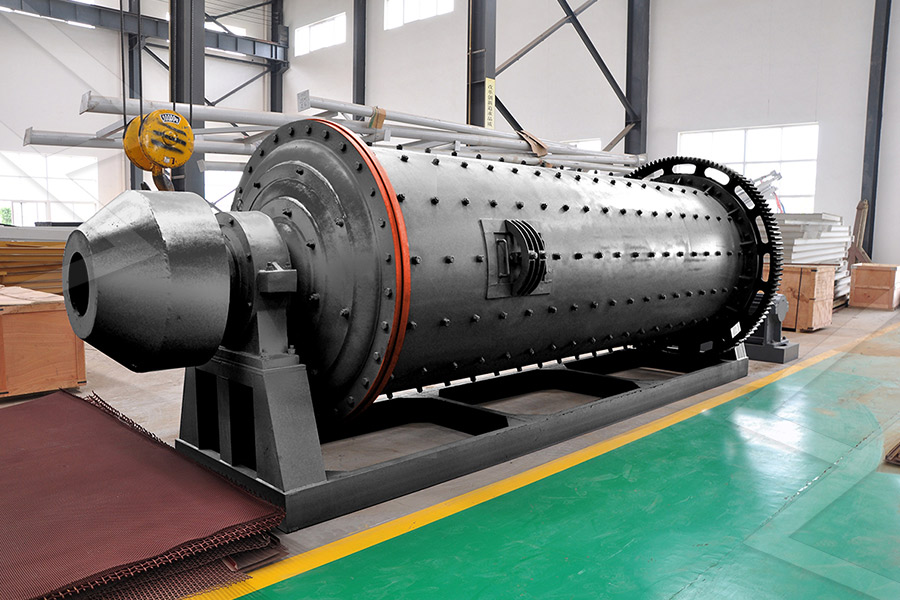

Tutorial: Size Reduction of Solids A material is crushed in a Blake jaw crusher such that the average size of particle is reduced from 50 mm to 10 mm with a consumption of energy at the rate of 13 kW/(kg/s) What will 2024年8月6日 Double Toggle Jaw Crusher: Similar to the single toggle jaw crusher, this type has two jaws that are hinged at the top and bottom The movement of the jaws creates a compressive force to crush the material Blake Jaw Crusher: This type of jaw crusher has a fixed feed area and a variable discharge area It is used to crush materials with Jaw Crusher for Sale Compare Prices SuppliersThe powerful jaw crusher is capable of a variety of tasks with its large underbelt clearances, and is equipped with a hydraulic raise and lower facility on the main conveyor as standard There are a number of features to minimize operator intervention whilst maximizing their safety, such as the selflocking hopper and jaw level sensor which Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher 2022年2月3日 MOBILE JAW CRUSHER TECHNICAL SPECIFICATION The QJ241 is the most compact model in the world leading series of Sandvik tracked jaw crushers This highly productive unit is built to tackle the most difficult applications with SANDVIK QJ241 MOBILE JAW CRUSHER SRP

.jpg)

jaw crusher 百度百科

Jaw crusher machine uses motor as its power Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and sidelee board can be crushed and discharged through the 2023年2月21日 A double toggle jaw crusher is a type of jaw crusher where the moving jaw is suspended from an eccentric shaft that is positioned on the top of the crusher The swing jaw is moved by a cam or pitman mechanism, acting like a lever The double toggle jaw crusher is designed for crushing hard and abrasive materials, with its unique features The Ultimate Guide to Jaw Crushing Machines: Types2024年4月25日 Size and Capacity: The size and the capacity of jaw crusher have a considerable effect on the price of the crusher A small jaw crusher having a 250x400mm feed opening and a capacity of 520 tons Jaw Crusher Price Guide: Everything Buyers Need 2022年11月21日 The singletoggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) 1,200 rpm possible All data are intended as a guide only The machine capacity depends on the grain dis tribution as well as the characteristics and theIndustrial Solutions Jaw crushers ThyssenKrupp

Jaw Crushers Manufacturer in India Puzzolana

2 天之前 Jaw Crushers Designed to crush ROM feed material for demanding quarrying, mining, and demolition purposes With their unique Elliptical motion of the swing jaw Crushers, ensure highly efficient This video shows the analysis of the jaw crushing process for different materials (iron ore, limestone and granulite) The Tavares Breakage model in EDEM allows accurate modelling of the real process by simulating a continuous feedrate and the complex motion of the swing jaw The crushing process for different materials can be optimized and the need EDEM simulation of Jaw Crusher2024年9月7日 A jaw crusher with a wider and shallower jaw can be referred to as a granulator They are also commonly used for secondary and tertiary crushing as they can produce a relatively smaller material size while maintaining an impressive output Model of machine Feed Opening In (MM) recommended Max feed sizeJaw Crushers Sanland Equipment2024年9月9日 The C5X Jaw Crusher features a welldesigned crushing chamber and outstanding motion characteristics, boasting a larger stroke and higher speed that enhance the crushing efficiency The entire machine offers improved reliability and is wellsuited for diverse working conditions It is capable of coarse and medium crushing of various C5X Jaw Crusher Industrial Technology Group

.jpg)

Jaw Crusher: Range, Working Principle, Application

2022年2月22日 A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also Retsch : 产品 : 粉碎设备 : 颚式粉碎仪Optimalisasi Closed Side Setting (CSS) Jaw Crusher Achmad Addinnulhaq * Prodi Teknik Pertambangan, Fakultas Teknik, Universitas Islam Bandung, Indonesia *Achmadaddin26@gmail Abstract Along with the very rapid development of development, be Optimalisasi Closed Side Setting (CSS) Jaw CrusherThe main parts and main technical parameters of a jaw crusher are presented below 1 Feed Chute 2 Drive Flywheel 3 Vbelts 4 Electric motor 5 Motor Stand 6 Settings and Damping Group 7 Hydraulic Cylinder 8 Toggle Plate 9 Swing Jaw 10 Discharge 11 Fixed Jaw Parts G: Gape width,WHAT IS A JAW CRUSHER? MEKA

.jpg)

Jaw Plates: Everything You Should Know

2023年2月16日 Jaw plates are an essential component of the jaw crusher and play a critical role in crushing the material Selecting the right jaw plates is crucial for optimizing the performance and longevity of the crusher By Answer to Tutorial: Size Reduction of Solids 1 A material is CheggTutorial: Size Reduction of Solids 1 A material is Jaw Crusher; Description Minex MJC series of single toggle jaw crushers are mainly used for heavyduty continuous applications as primary crushers in aggregates production, mining operations and recycling applications This series includes models of various sizes that are designed to deliver maximum productivity at the lowest operating costsJaw Crusher Minex Solutions2023年12月26日 22 Kinematic model The moving jaw of the crusher is suspended in the link arm at the bottom and in an eccentric bushing at the top 115 The position of the jaw over time can be determined byA Fundamental Model of an Industrialscale Jaw Crusher

Jaw Crusher Eriez

Jaw Crusher 100 x 150 L07000 100 x 150 (4" x 6") Jaw Crusher with: 22 kW Electrical motor; Starter with overload protection; Cast Iron construction with Mild Steel base frame; Vbelt driven with pulley flywheel guard Standard Gaurds; Reversible Manganese Steel Jaws; Inlet Size: 4" x 6"(100 x150mm) Maximum Feed Size: 80 mm Discharge 6 天之前 A small jaw crusher is a type of jaw crusher that is specifically designed for smallscale operations, laboratories, or where space and capacity constraints exist These crushers are suitable for crushing small amounts of hard materials into smaller, more manageable pieces Laboratories: For sample preparation and testingSmall Jaw Crusher TAYMACHINERY2024年2月18日 The jaw crusher diagram is instrumental when it comes to adjustments for altering the granularity of the output One critical metric is the Closed Side Setting (CSS)—the smallest gap between the jaws during the crushing cycle Adjusting CSS is a straightforward affair and can make a significant difference in your output’s size and qualityJaw Crusher Diagram: Simplified Guide JXSCEbco Jaw Crusher Features: High tonnage capacity of up to 1000 tons/hour and low operating cost Designed for the toughest rock material with compressive strength of up to 320 MPa Supplied for Primary coarse crushing and secondary fine crushing within the rock reduction plantJAW CRUSHER Ebco Mining

The Importance of Jaw Crusher Design Features in Crushing

2023年2月28日 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industryThey are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more manageable sizes The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore 2024年2月5日 A jaw crusher operates by the movement of a movable jaw in relation to a fixed one to crush large rocks into smaller pieces It does this by using a spinning shaft that makes the movable jaw move back and How Does a Jaw Crusher Work? A Simple GuideMechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly used Jaw Crushers AGGRETEK Jaw Crushers for 2024年2月22日 If you think a jaw crusher could be the right tool for the job, contact Boom and Bucket to see our wide array of used work vehicles at affordable prices Visit Boom Bucket to buy and sell your machinery Intro to Aggregate Equipment: The Jaw Crusher

.jpg)

Jaw Crusher: What Is It How Does It Work? VYKIN Crushers

5 天之前 But many people don’t know that jaw crushers come in all shapes and sizes, from small tabletop models to massive industrial machines So what exactly is a jaw crusher, and how does it work? What Is A Jaw Crusher, And How Does It Work? A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust2022年9月22日 Jaw crusher adalah penghancur pola dasar yang digunakan untuk membongkar batu dan batu; dengan jaw crusher, Anda dapat menghancurkan semua jenis material dengan berbagai ukuran tergantung kebutuhan Anda Rahang bergerak memberikan tekanan Tentang Jaw Crusher Omnia Machinery4 天之前 Model: VYKIN 49JC Configuration: Jaw crusher Power System: Dieseldirect drive Engine: Yanmar tier 4 certified EPA diesel engine (48HP 355kW) Fuel Consumption: 13 – 21 gal/hr, 264 gal capacity Electrical Control: Yes, wireless remote standard Hydraulic Control: Yes, tracks (rubber) Capacity: 2049 TPH Crushing material: softertomedium VYKIN 49JC Mobile Small Tracked Jaw Crusher VYKIN Jaw crusher walkaround Join Geoffrey Faber on a tour around the RM J110X mobile jaw crusher RM J110X Specs Capacity: 450 tph 496 TPH: Inlet opening: 1,100 x 700 mm 44" x 28" Crusher unit: Single toggle jaw crusher Single toggle jaw crusher : Drive: Dieselhydraulic Dieselhydraulic : Engine:RM J110X Mobile Jaw Crusher RUBBLE MASTER

.jpg)

Jaw Crushers Mt Baker Mining and Metals

Complete and ready to run including jaw crusher, belts, motor, fullenclosure guards, all integrated on a steel skid; Oversized bearings and castings, robust construction, longwearing cast manganese steel jaw plates; Optional steel stand; Sizes: 6”x 10” through 20” x 30″ jaw opening;Jaw Crusher Machine The Mini mobile crusher is the perfect machine for all small to moderate crushing projects where construction and demolition “waste” materials can be recycled onsite, providing a great solution for builders, landscape gardening, recycling, demolition, infrastructure, relief aid and medium sized aggregate crushing applicationsMini Mobile Jaw Crusher Wuxi Pinnacle Mechanical 2024年4月6日 Types of Jaw Crushers: There are two types of Jaw Crushers: Single Toggle and Double Toggle Single Toggle: The single toggle movement jaw crusher, more compact than double toggle The Ultimate Guide to Jaw Crushers PuzzolanaThe 4000 is a 400mm x 170mm jaw action crusher Instant hydraulic adjustable jaws allow output product sizes to range from 20mm up to 80mm Dust suppression is fitted as standard, by means of fine water spray RR 4000 Red Rhino Crushers

CHPL332 Size Reduction of Solids Tutorial

Tutorial: Size Reduction of Solids A material is crushed in a Blake jaw crusher such that the average size of particle is reduced from 50 mm to 10 mm with a consumption of energy at the rate of 13 kW/(kg/s) What will 2024年8月6日 Double Toggle Jaw Crusher: Similar to the single toggle jaw crusher, this type has two jaws that are hinged at the top and bottom The movement of the jaws creates a compressive force to crush the material Blake Jaw Crusher: This type of jaw crusher has a fixed feed area and a variable discharge area It is used to crush materials with Jaw Crusher for Sale Compare Prices SuppliersThe powerful jaw crusher is capable of a variety of tasks with its large underbelt clearances, and is equipped with a hydraulic raise and lower facility on the main conveyor as standard There are a number of features to minimize operator intervention whilst maximizing their safety, such as the selflocking hopper and jaw level sensor which Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher 2022年2月3日 MOBILE JAW CRUSHER TECHNICAL SPECIFICATION The QJ241 is the most compact model in the world leading series of Sandvik tracked jaw crushers This highly productive unit is built to tackle the most difficult applications with SANDVIK QJ241 MOBILE JAW CRUSHER SRP

.jpg)

jaw crusher 百度百科

Jaw crusher machine uses motor as its power Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and sidelee board can be crushed and discharged through the 2023年2月21日 A double toggle jaw crusher is a type of jaw crusher where the moving jaw is suspended from an eccentric shaft that is positioned on the top of the crusher The swing jaw is moved by a cam or pitman mechanism, acting like a lever The double toggle jaw crusher is designed for crushing hard and abrasive materials, with its unique features The Ultimate Guide to Jaw Crushing Machines: Types