Mini Cement Raw Meal Circuit

.jpg)

Optimization of a fully airswept dry grinding cement raw meal

2015年4月1日 Conventional twocompartment fully airswept KHD Humboldt Wedag® raw meal ball mill operating in closed circuit with a static separator was modelled and Abstract: The raw meal quality control of cement is an important link in cement production The pass rate of raw meal quality control has a crucial impact on clinker calcination Application of Intelligent Control in Raw Meal Quality Control2011年10月24日 Figure 1 Flow chart of raw meal production In the closed circuit process demonstrated, the raw materials’ feeding is performed via three weight feeders, firstly Effective Optimization of the Control System for the 2018年7月1日 Cement manufacturing is a process that combines varieties of unit operations including raw meal handling, pyrometallurgy and comminution Comminution Energy and cement quality optimization of a cement grinding circuit

Effective Optimization of the Control System for the

2023年12月18日 In cement industry a huge amount of efforts in process control have been dedicated on raw meal homogeneity as it is the main factor influencing the clinker activity 2011年7月1日 The present study is aiming to develop a simulator of the mixing process in production installations of raw meal comprising all the main characteristics of the process and raw materialsEffective Optimization of the Control System for 2015年4月1日 The full scale model parameters were used to simulate the raw meal mill grinding circuit with the aid of JKSimMet Steady State Mineral Processing Simulator Optimization of a fully airswept dry grinding cement raw meal 2011年10月24日 cement products quality have focused on raw meal homogeneity as it is the main factor influencing the clinker activity [1] Primarily the control and regulation is Effective Optimization of the Control System for the

.jpg)

Effective optimization of the control system for the cement raw meal

2011年7月1日 This paper represents the identification of a raw blending system in a cement factory for advanced process control using three different linear multivariable 2024年4月26日 Consequently, in order to indirectly respond to the homogeneity of raw meal composition from the physical properties of cement, the raw materials obtained from the model processing of each Evaluation and Analysis of Cement Raw Meal 2019年7月29日 Abstract: The difference between the measured data using an infrared sensor and those using the Xray fluorescence sensor of raw meal composition in a cement plant was big and timevarying, which cannot meet the need of automatic cement manufacturing process control To improve the measurement accuracy, the infrared Improving Measurement Accuracy in Cement Raw Meal The calcium looping CO 2 capture process, CaL, represents a promising option for the decarbonisation of cement plants, due to the intrinsic benefit of using the spent CO 2 sorbent as a feedstock for the plant The Calcination kinetics of cement raw meals under

.jpg)

Effective Optimization of the Control System for

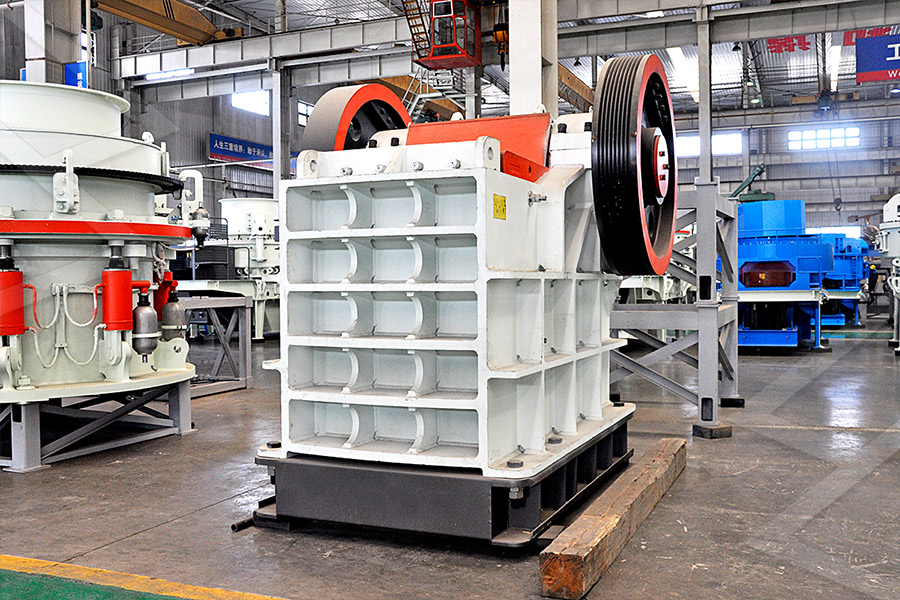

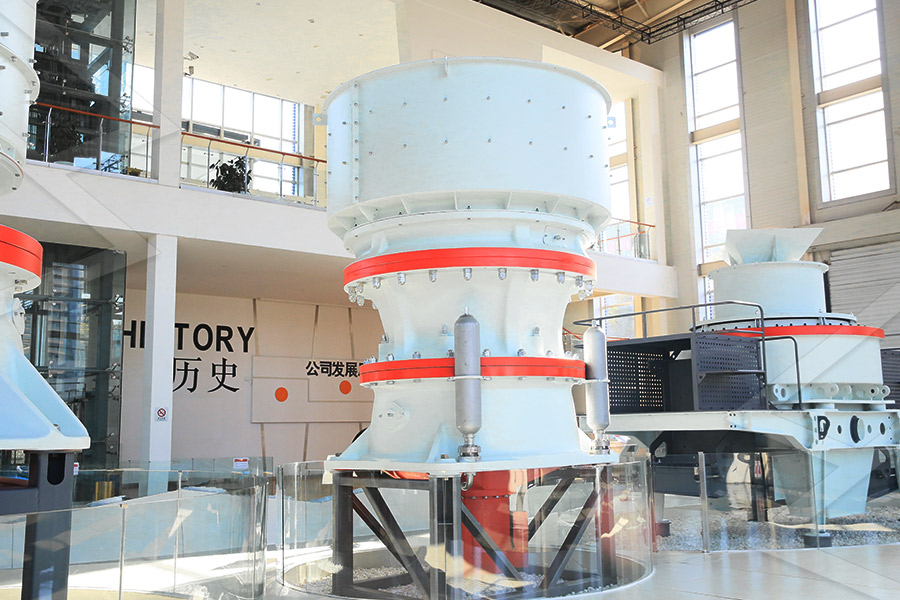

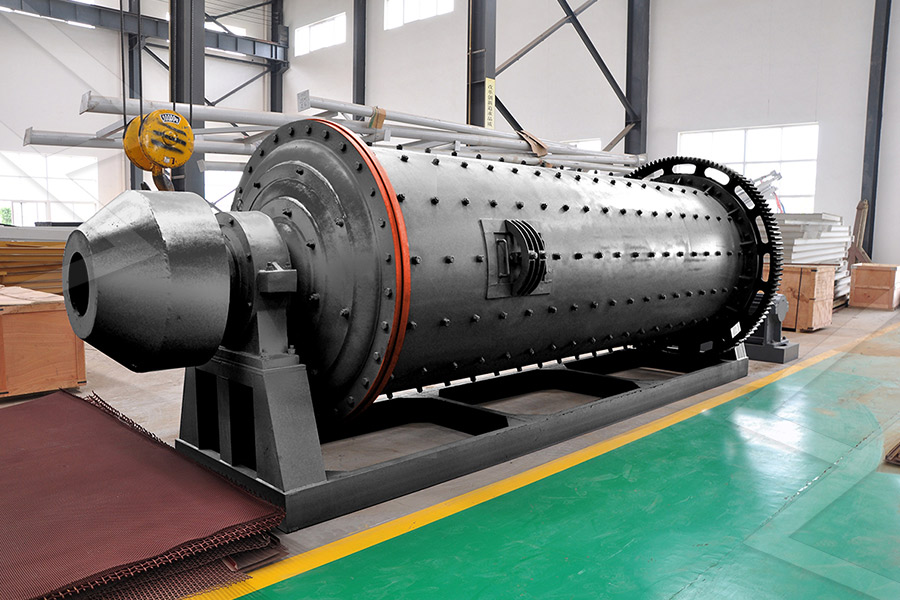

2012年5月1日 The main factors that influence the quality of the raw meal during its production in a ball mill and storage in stock and homogenisation silos of continuous flow are investigated2023年3月1日 β [1 − α; p 2; n − p − 1 2] = (1–α) th quantile of β [p 2; n − p − 1 2] distribution For α = 005, the number of outliers is 44 among 280 data corresponding to an upper limit control U C L M a h a l a n o b i s = 455 as illustrated in Fig 3The results of these outliers have been carefully analyzed by a process expert from the cement plant Efficient machine learning model to predict fineness, in a vertical raw The cement roller press is a type of material crushing machine which is often used in cement plants It usually works together with a ball mill to form a pregrinding or finalgrinding system for the grinding of raw materials, coal, and clinker Compared with the traditional tube mill and ball mill, the roller press has lower energy consumption and higher production Hydraulic Roller Press in Cement Plants AGICO Cement 2019年7月20日 Raw meal storage, homogenization and Kiln feeding 6 Pyroprocessing (Raw meal preheating, calcination Clinkerization, clinker cooling, additive) are proportioned and ground in Cement mill (one Closed circuit ball mill in line 1 and two Roller press+closed circuit ball mill in line 2) based on the type ofCEMENT PRODUCTION AND QUALITY CONTROL

Effective Optimization of the Control System for the

2023年12月18日 𝑖 I 𝑎 P Q N𝑎 P𝑖 K J 𝑎 K N and the measured one Finally = 100 ∙𝐶 28 ∙ + 118 ∙𝐴+ 065 ∙ (1)2020年8月27日 The 5stage suspension preheater cyclone is the device inside which the cement raw meal performs heat exchange with hot gas from the rotary kiln and is preheated It is one of the key equipment in the cement clinker production line, and its efficiency directly affects the production efficiency of the whole plant and product clinker quality The index Preheater Cyclone Thermal Efficiency Analysis AGICO Cement To improve customer service, cement manufacturers have started to automate the handling of loose or packaged cement in truck transport by using flexible selfservice systems An initial requirement is the automatic control of the cement loading process so that the trucks load the quantity required by the cement customer and do not exceed the loading Roller press circuits for finish grinding of cement raw 2021年1月1日 1 Introduction The control of the raw mill feed before the raw mill and the raw meal after the mill is still indispensable Because of the complexity and the significance of the control process, various automated systems are available for sampling and analysing the raw mix as well as for adjustment of the mill weight feeders according to the raw meal Influence of raw meal composition on clinker reactivity and cement

Cement Manufacturing Process INFINITY FOR

Homogenizing silo (Raw meal silo) This is an area where the raw meal is stored temporarily It has two roles: blending and storing Here Blending is an act of mixing or homogenizing of raw meal using compressed air to 2022年10月4日 The composition of cement raw materials was detected by nearinfrared spectroscopy It was found that the BiPLSSiPLS method selected the NIR spectral band of cement raw materials, and the partial least squares regression algorithm was adopted to establish a quantitative correction model of cement raw materials with good prediction Rapid Detection of Cement Raw Meal Composition Based on 2023年7月4日 The use of hightemperature Xray diffraction (HTXRD) to study the mass transfer of raw meal constituents towards forming clinker phases and the occurrence of free lime (calcium oxide), also known as burnability, was assessed A measuring strategy with temperature ranging from 1000°C to 1450°C was developed and compared with a Phase evolution and burnability of cement raw meal Advances in Cement 2024年9月1日 Determining the content of components in cement raw meal is vital in Portland cement manufacturing Nearinfrared spectroscopy (NIRS)enables rapid, safe, and accurate quantitative analysis of the primary constituents of cement raw meal (CaO, SiO 2, Al 2 O 3, and Fe 2 O 3), thereby assisting the cement industry in reducing the time delay Quantitative determination of oxides in cement raw meal

Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw Mill

AGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System Cement vertical mill, also called roller mill, is another raw mill commonly used in cement pared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play Drying of moisture in raw materials is required for effective grinding and subsequent handling of raw meal This is achieved normally by ducting part of the kiln exhaust gas through the mill with inlet temperatures of up to 320°C Inertization of coal mill circuit and fine coal bins with CO2, N2 or CO2+N2 to replace O2 which promotes Raw Material DryingGrinding Cement Plant Optimization2019年4月21日 storage and blending of Raw Meal Continuous homogenization can be performed in this silo to maintain uniform desired quality 116 Coal Mill The raw coal, received by rail/road is stored in yard and crushed to 30 mm size by Reversible Impact Hammer and roll crushers Crushed raw coal is fed to the coal mill for grindingOVERALL INCREASE IN EFFICIENCY IN RAW MEALSThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The Vertical Roller Mill Operation in Cement Plant

LIBS combined with SGSPXY spectral data preprocessing for cement raw

2024年2月20日 Rapid testing of cement raw meal plays a crucial role in the cement production process, so there is an urgent need for a fast and accurate testing method In this paper, a method based on the SavitzkyGolay (SG) smoothing and sample set partitioning based on joint x y distance (SPXY) s 2019年5月5日 Effect of Humidity on Determination of Main Components in Cement Raw Meal Using Near Infrared Spectroscopy and Compensation Method XIAO Hang, YANG Zhenfa, ZHANG Lei *, ZHANG Faye, SUI Qingmei, JIA Lei, JIANG Mingshun College ofEffect of Humidity on Determination of Main Components in 2017年1月21日 The values are equivalent and the chemical composition of the cement raw meal is the one expected, so the cement raw meal is well homogenized 33 Burnability study of cement raw meals The reactivity of the cement raw meals was evaluated on the basis of free lime (fCaO) contents after sintering at 1200, 1300, 1400 and 1450 °CValorisation of recycled concrete sands in cement raw meal for cement 2019年9月1日 The use of raw meals as a CO 2 sorbent is a relatively recent concept, but it is an interesting alternative to evaluate with the aim of achieving zero emissions for cement manufacturing plants [14, 19, 20, 22, 23, 30, 31]Raw meal is a mixture of fine powdered limestone, silica, alumina and iron oxide and only the CaO present in the limestone is Reactivity of calcined cement raw meals for carbonation

Application of Wavelet Transform in Automatic Batching of Cement Raw Meal

In order to reduce the large hysteresis effect of raw meal preparation in domestic cement plants, the nearinfrared online analyzer is used together with the expert system to gradually replace the offline laboratory testing, which greatly reduces the timeconsuming detection of raw meal components and improves production efficiency However, the production 2016年10月5日 1 Introduction Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns In recent EnergyEfficient Technologies in Cement GrindingDOI: 101016/S08926875(01)001601 Corpus ID: ; Modelling cement grinding circuits @article{Benzer2001ModellingCG, title={Modelling cement grinding circuits}, author={Hakan Benzer and Levent Ergun and A J Lynch and Muammer {\"O}ner and A Gunlu and Ilkay B Celik and Namık A Aydogan}, journal={Minerals Engineering}, Modelling cement grinding circuits Semantic Scholar2011年7月1日 The objective of the present study is to use a reliable model of the raw meal mixing process dynamics in raw meal production installations, in order to tune effectively PID controllers, thus Effective Optimization of the Control System for the Cement Raw Meal

Improved Prediction of Oxide Content in Cement Raw Meal

2023年10月5日 Accurate determination of CaCO3, SiO2, Fe2O3 and Al2O3 in cement raw meal requires minimizing scattering effects from the spectrum, but selecting an appropriate pretreatment technique is often challenging In this paper, we enhance the predictive ability of NIRS for determining the four oxides in cement raw meal by implementing sequential Mini Cement Plant Hot Sale; Cement Plant 700 ~ 2000tpd; Cement Plant 2500~7000tpd; Raw Meal Preparation Menu Toggle Cement Crusher; Jaw Crusher; Hammer Crusher; Cone Crusher; Impact Crusher; Rotary Dryer; The closedcircuit grinding system formed by a ball mill and a separator is a type of widely used cement milling system in cement How to Improve Cement Ball Mill Performance in Closed Circuit 2021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550–600 million Review on vertical roller mill in cement industry its The investigation described is concerned with multistage preheaters for cement raw meal which are followed by a calcining stage The residence time of the meal in the calcining stage to achieve complete calcination is calculated, and also the fuel consumption needed for preheating and complete calcinationPreheating and Complete Calcination of Cement Raw Meal

.jpg)

[PDF] Fluidized bed calcination of cement raw

2021年3月3日 The chemical and thermal processes associated with the decarbonation and fuel combustion in the cement kiln process produce a large amount of carbon dioxide (CO 2 ) contributing with around 8 % of 2011年10月24日 and the raw meal composition In Figure 1 a typical flow chart of raw meal production is shown Figure 1 Flow chart of raw meal production In the closed circuit process demonstrated, the raw materials’ feeding is performed via three weight feeders, firstly feeding a crusher The crusher outlet goes to the recycle elevator and from there itEffective Optimization of the Control System for the The raw meal quality control of cement is an important link in cement production The pass rate of raw meal quality control has a crucial impact on clinker calcination Cement production is a complex largescale system control process, the production process has randomness, hysteresis and uncertainty, the quality control of raw meal has a certain Application of Intelligent Control in Raw Meal Quality ControlDownload scientific diagram Flow chart of raw meal production from publication: Effective Optimization of the Control System for the Cement Raw Meal Mixing Process: II Optimizing Robust PID Flow chart of raw meal production Download Scientific

.jpg)

CF raw meal silo FLSmidth Cement

2023年8月17日 efficiency, all the raw meal in a silo must be kept in constant movement towards the outlets Furthermore, the raw meal must pass through the silo in flow zones with different residence time The CF silo complies with these demands It extracts raw meal at different rates from several outlets in the silo bottom and mixes the stream from these 2024年9月4日 Our Plant Introduction Asia Cement’s Pukrang Plant consists of two production lines with a current installed capacity of 5 million tons of cement per year The plant is located at Tambon Pukrang, Amphur Pra Buddhabat, Saraburi Province on an area of more than 1,000 rai (about 400 acres) In 1993 the first production line was started Asia Cement Plc2022年10月4日 have introduced online analyzers of cement raw meal elements They detect cement raw meal components online and reduces labor intensity by automatic proportioning of cement raw meal However, high maintenance cost and radioactive sources are harmful to the environment and field workers As a quantitative analysis method, near Rapid Detection of Cement Raw Meal Composition Based on the analysis of the process of cement raw meal vertical milling system, this paper points out the key control output in the process, the mill vibration, and designs a controller to control it by iterative learning and modelfree adaptive control methods Firstly, the PPD state observer is designed for dynamic linearization, and the controller design is based ModelFree Adaptive Controller Design Based on DataDriven ILC Cement

What Is Raw Meal (FARIN) MEKA

The raw material with the desired chemical and physical characteristics is called FARIN Clinker, as one of the main constituents of cement, is produced from farin following heat treatment at 1500°C What is clinker? Clinker, a mixture of clay and limestone, is raw meal that has been heat treated It can be considered as the initial state of 2024年6月3日 The component analysis of raw meal is critical to the quality of cement In recent years, nearinfrared (NIR) has been emerged as an innovative and efficient analytical method to determine the oxide content of cement raw meal This study aims to utilize NIR spectroscopy combined with machine learning and chemometrics to improve the Enhanced prediction of cement raw meal oxides by near 2019年7月29日 Abstract: The difference between the measured data using an infrared sensor and those using the Xray fluorescence sensor of raw meal composition in a cement plant was big and timevarying, which cannot meet the need of automatic cement manufacturing process control To improve the measurement accuracy, the infrared Improving Measurement Accuracy in Cement Raw Meal The calcium looping CO 2 capture process, CaL, represents a promising option for the decarbonisation of cement plants, due to the intrinsic benefit of using the spent CO 2 sorbent as a feedstock for the plant The Calcination kinetics of cement raw meals under

.jpg)

Effective Optimization of the Control System for

2012年5月1日 The main factors that influence the quality of the raw meal during its production in a ball mill and storage in stock and homogenisation silos of continuous flow are investigated2023年3月1日 β [1 − α; p 2; n − p − 1 2] = (1–α) th quantile of β [p 2; n − p − 1 2] distribution For α = 005, the number of outliers is 44 among 280 data corresponding to an upper limit control U C L M a h a l a n o b i s = 455 as illustrated in Fig 3The results of these outliers have been carefully analyzed by a process expert from the cement plant Efficient machine learning model to predict fineness, in a vertical raw The cement roller press is a type of material crushing machine which is often used in cement plants It usually works together with a ball mill to form a pregrinding or finalgrinding system for the grinding of raw materials, coal, and clinker Compared with the traditional tube mill and ball mill, the roller press has lower energy consumption and higher production Hydraulic Roller Press in Cement Plants AGICO Cement 2019年7月20日 Raw meal storage, homogenization and Kiln feeding 6 Pyroprocessing (Raw meal preheating, calcination Clinkerization, clinker cooling, additive) are proportioned and ground in Cement mill (one Closed circuit ball mill in line 1 and two Roller press+closed circuit ball mill in line 2) based on the type ofCEMENT PRODUCTION AND QUALITY CONTROL

Effective Optimization of the Control System for the

2023年12月18日 𝑖 I 𝑎 P Q N𝑎 P𝑖 K J 𝑎 K N and the measured one Finally = 100 ∙𝐶 28 ∙ + 118 ∙𝐴+ 065 ∙ (1)2020年8月27日 The 5stage suspension preheater cyclone is the device inside which the cement raw meal performs heat exchange with hot gas from the rotary kiln and is preheated It is one of the key equipment in the cement clinker production line, and its efficiency directly affects the production efficiency of the whole plant and product clinker quality The index Preheater Cyclone Thermal Efficiency Analysis AGICO Cement To improve customer service, cement manufacturers have started to automate the handling of loose or packaged cement in truck transport by using flexible selfservice systems An initial requirement is the automatic control of the cement loading process so that the trucks load the quantity required by the cement customer and do not exceed the loading Roller press circuits for finish grinding of cement raw 2021年1月1日 1 Introduction The control of the raw mill feed before the raw mill and the raw meal after the mill is still indispensable Because of the complexity and the significance of the control process, various automated systems are available for sampling and analysing the raw mix as well as for adjustment of the mill weight feeders according to the raw meal Influence of raw meal composition on clinker reactivity and cement