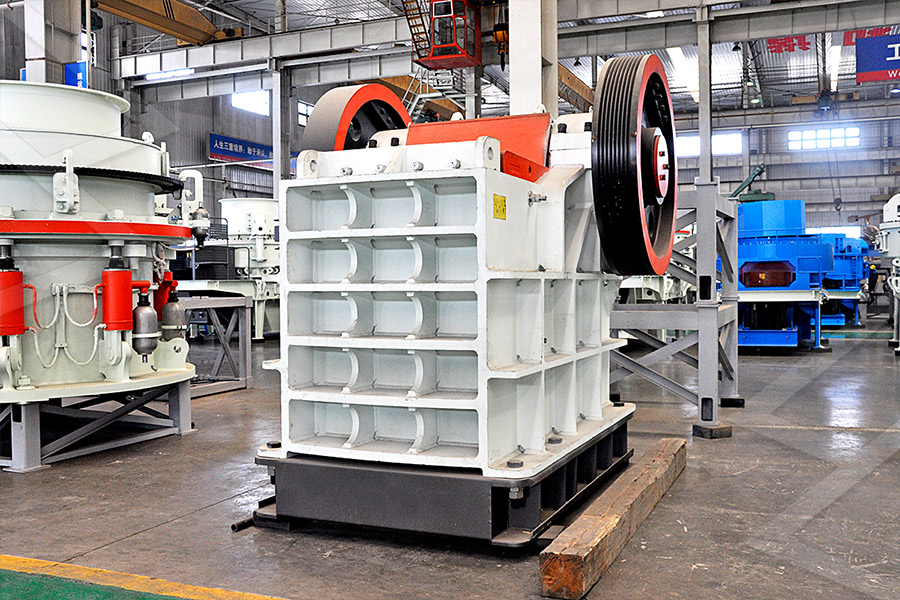

Instalation Of Jaw Crusher Mechine

.jpg)

Jaw crushr operate manual: how to install, repair

2022年9月30日 1 Preparation of jaw crush foundation Jaw crushers are usually installed on concrete foundations, with a drainage trough reserved for the foundation, preferably with a slope of less than 50 degrees Due This article will explain in detail the installation and use of the jaw crusher What is the jaw crusher for? The jaw crusher belongs to primary and secondary crushing equipment in the mining industry and plays a vital How To Install And Use Jaw Crusher Properly?2022年12月12日 As the main primary stone crusher, jaw crusher is mainly used to break large and hard materials In order to crush the hard materials, the jaw crusher is How to Install Jaw Crusher Properly sanmechinaThe skills and notes of the installation of jaw crusher, the parts how to install, such as frame, shaft and bearing, connecting rod, toggle plateInstallation of Jaw Crusher Skills and Notes

Installation, operation and maintenance of jaw crusher

2024年7月12日 The jaw crusher should be installed on a concrete foundation, and in order to reduce vibration, wooden or rubber pads should be added between the foundation and 2023年2月21日 A jaw crushing machine is a type of equipment used to break down hard materials, such as rocks, minerals, and ores It consists of a fixed jaw plate and a movable jaw plate that is positioned in a V The Ultimate Guide to Jaw Crushing Machines: 2018年12月26日 Content Crushers for Bulk Materials Crushers and breakers are used to reduce size of mined and quarried material for further processing or to size suitable for Construction, Working and Maintenance of Practical To ensure the efficient operation of a jaw crusher, proper installation is crucial This article will provide a detailed explanation of the jaw crusher installation process, including a Jaw Crusher Installation Process Diagram – stone cruxder

jaw crusher 百度百科

Jaw crusher machine uses motor as its power Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track Therefore, the materials in The powerful jaw crusher is capable of a variety of tasks with its large underbelt clearances, and is equipped with a hydraulic raise and lower facility on the main conveyor as standard There are a number of features to Sandvik QJ341 Mobile Jaw Crusher – World instalation of jaw crusher mechine Home Page Back Mobile Jaw Crusher is designed more reasonable and compact, including installation in broken machine bracket Shang of broken machine, 31 Jaw crusher; 32 Gyratory crusher; 33 Cone crusher 331 Compound cone crusher; Jaw crushers are heavy duty machines and hence need to instalation of jaw crusher mechine hebergementvosges2023年2月15日 a template of jaw crusher checklist 2Do the lubrication job well The lubrication of the interface between the parts of the jaw crusher is very important It can minimize the friction generated during the The Most Practical Jaw Crusher Repair and

Jaw Crusher: Range, Working Principle, Application

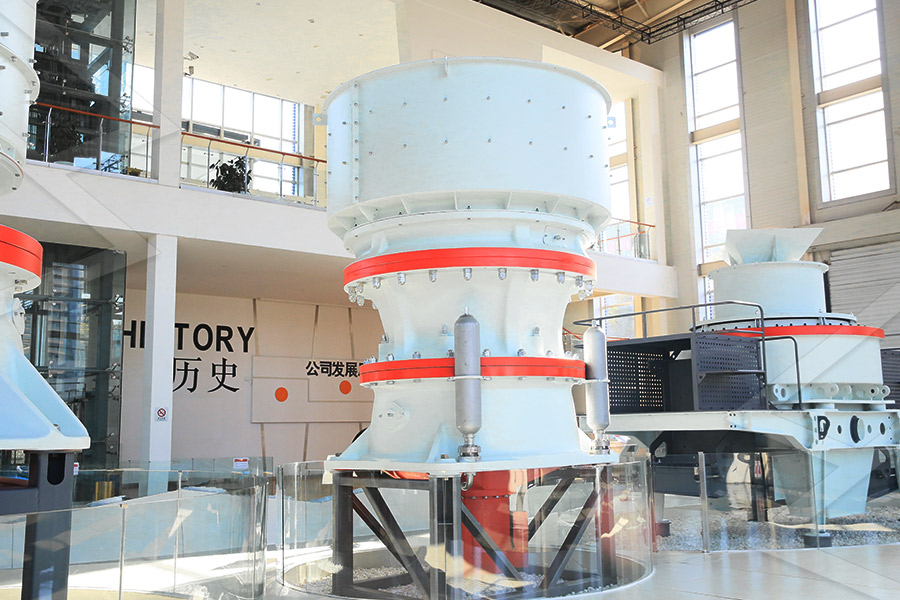

2022年2月22日 A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it 2020年3月19日 Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers cannot accept all material sizes Any material fed to the crusher must be presized for that particular crusher (usually 200mm or less)Selecting the right crusher for your operations QuarryThe Jaw Crusher is classified under our comprehensive Mining Crusher rangeIn China, identifying reputable mining crusher suppliers involves thorough research, checking credentials, customer reviews, and obtaining samples for quality verification Leveraging industry platforms and exhibitions also aid in connecting with reliable suppliers for Jaw Crusher MadeinChinaFind here Jaw Crusher, Heavy Duty Jaw Crusher manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Jaw Crusher, Heavy Duty Jaw Crusher across IndiaJaw Crusher Heavy Duty Jaw Crusher Latest Price,

.jpg)

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

The crushing performance of a jaw crusher depends on the operational sloped angle of the jaws (1) and the ir shape, the speed and the movement behavior of the fourbar linkage During one revolution of the fourbar linkage, the breaking jaw moves in vertical and k750 jaw crusher:hooklift jaw crusher The K750 combines superior crushing performance with the ability to transport with a standard hook lift truck From unloading to operating in less than 5 minutes, the K750 jaw harnesses the power of the onboard Diesel electric generator to crush 0400mm rock, concrete and brick at typically 50100tphJaw Crushers — Nordmann2019年4月25日 Jaw Crusher Product overview As a leading Jaw Crusher manufacturer in China, GATOR is committed to various jaw crushers and screening equipment design, manufacturing and sales, The jaw crushers can crush various material with compressive resistance less than 320Mpa, Feed size is from 125mm to 750mm, and with features of GATOR series JawCrusherBest JawCrusherGATOR US2023年10月16日 The jaw crusher must be regularly maintained to avoid breakdowns, as mining companies rely heavily on this machinery to help them process their materials without delays Overall, the jaw crusher is an essential piece of equipment widely used across the mining and construction industries and has proven to be an effective way of breaking The Mechanics of Crushing: Understanding the Jaw Crusher

(PDF) Design and Analysis of Swing Jaw Plates of

Jaw Crusher machine breaks minerals, high strength stones and lumps The stiffness of swing jaw plate and the strength of the rock are not depending to each other because stiffness has not been varied with changes in rock We also provide Jaw crusher import data and Jaw crusher export data with shipment details +91 crusher HS Codes HS Code of Jaw crusher Import Jaw The presence of a larger feed opening ensures increased material intake so that the rocks enter the jaw crusher’s cavity without restrictions Protective Seals The bearings are protected by greasepurged labyrinth dust seals that ensures longer life Product Highlights Max Feed Size: 650 mm / 26 inch:Jaw Crusher Minex SolutionsAs a top crusher manufacturer, Propel machines efficiently compress and break rocks, ensuring peak crushing efficiency at the lowest cost per ton JAW CRUSHERS Propel AVJ series single toggle Jaw Crusher offers maximum possible fatigue strength and best reliability with various mounting possibilities The fullywelded sturdyCrusher Machine Manufacturer Propel Industries Coimbatore

.jpg)

Dynamics Analysis and Chaos Identification of Compound Pendulum Jaw

2022年12月24日 A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the LN contact force model and modified Coulomb friction force model The correctness of the dynamic model is verified by MATLAB and Adams comparison simulation, and the 5 天之前 Today, this pioneer crusher is the standard for all jaw crushers Types Of Crusher Machines There are various types of stone crushers Each is different in crushing application depending on the material to be destroyed, the desired product size, the feed size, and the crusher’s capacity Still, below are some common types of crusher machinesCrusher Machines: 10 Types to Know Komplet America2023年2月28日 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industryThey are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more manageable sizes The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore The Importance of Jaw Crusher Design Features in Crushing Jaw crusher tooth plate is directly used for crushing ore parts Its structure is simple, but because of frequent contact with the ore, tooth plate is the crusher wear quickly So it is often needed to replace the parts There are two kinds of crosssection structures shape of the tooth plate, the smooth surface and the lattice surfaceInstallation of Jaw Crusher Skills and Notes JXSC Mine

.jpg)

Cedarapids JW42 Jaw Crusher MPS

2024年8月22日 The Cedarapids® CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke, 42” x 20’ (1067 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing machine Learn More about CRJ3042; MJ42 The MJ42 features the rugged JW42 Jaw Crusher for high production applications2023年9月30日 The jaw crusher angle and rotating mass type are considered to study all particle sizes and reduction ratios obtained for three different motor operation speeds: 1500, 2000, and 2500 rpm Coarse Investigation of vibrating jaw crusher experimental variables2023年2月22日 Stone crusher machines are essential tools in the construction industry, used to crush rocks and stones into smaller pieces for a variety of applications This guide provides an overview of stone A Comprehensive Guide to Stone Crusher 2018年4月15日 Kinematic Dynamic analysis is helpful for understanding and improving the design quality of jaw crushers and there is a scope to develop design dynamic analysis to jaw crusher attachment The machines which are use to break or compress materials mining operations purpose is a crushers, crushers are commonly classified with the help Design and Analysis of Swing Jaw Plates of Jaw Crusher

What Are The Pros And Cons Of Jaw Crushers? Mormak

The basic technology behind jaw crushers has been around for almost 200 years, although it has undergone all manner of refinements and improvements to make it more efficient and more reliable The main operating principle of a jaw crusher is the combination of fixed and moving jaw plates, between which material is crushed as force is applied to it2023年3月11日 Another advantage of using an impact crusher is that it has a relatively low operating costThe machine uses less energy than other crushers, such as jaw or cone crushers, and its impact force is more efficient at breaking down the material, resulting in less energy wasteHow Impact Crushers Work: A Comprehensive Guide AGICO2014年4月1日 Then lay the pitman from the jaw crusher on its side to work on bearings or place the gyratory main shaft upright When the hole is not in use, it must be covered Preventative and predictive maintenance is largely based on good planning and followup, including the discipline to follow visual inspection and lubrication schedules If a service Below the surface: Setting up an underground primary jaw crusherJaw crusher can reach the crushing ratio of 46 and the shape of final product is even It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is underjaw crusher 百度百科

Jaw Crusher Working Principle StudiousGuy

2 Both the structure and working of a jaw crusher are quite simple 3 The product size is quite small and can range up to millimetres 4 Repair and maintenance of a jaw crusher are convenient and easy 5 The reliability of a jaw crusher is significantly high 6 The broken parts of the jaw crusher are easy to replace Disadvantages of a Jaw 2023年2月21日 The hydraulic jaw crusher is ideal for crushing hard and abrasive materials, and it is commonly used in mining, metallurgy, building materials, and chemical industries One of the advantages of a hydraulic jaw crusher is its ability to adjust the discharge opening easily, allowing for a wider range of output sizes The Ultimate Guide to Jaw Crushing Machines: Types2020年11月8日 VPEmobilejawcrusherplant700x394 Jaw Mobile Crushing Station • Application: Sand quarry, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc 64 65Crusher; Crushing; and Classification Equipment PPT2023年2月23日 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries These machines are designed to crush large rocks and ores into smaller pieces Understanding Jaw Crusher Parts and Their

JAW CRUSHER RISK HAZARD ASSESSMENT

JAW CRUSHERPh0475 217 533Risk and Hazard Assessment is the identification of risks and hazards associated with the JAW CRUSHER Compliant Industries Group hazard and risk assessors are experienced 2023年12月30日 The foundation of a jaw crusher is the frame, which provides structural support and houses the eccentric shaft, which is a critical component for generating crushing motionIntroduction to Jaw Crushers: Understanding the Jaw Crusher is a basic sample preparation unit and is essential to address all primary size reduction requirements Desired crushing takes place when fed particles experience stress and the compressive pressure exerted by the jaw blade toggling action exceeds its fracture stress By this action the feed particles are crushed to smaller sizesEfficient Jaw Crusher for Coal Analysis Insmart Systems4 天之前 But many people don’t know that jaw crushers come in all shapes and sizes, from small tabletop models to massive industrial machines So what exactly is a jaw crusher, and how does it work? What Is A Jaw Crusher, And How Does It Work? A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dustJaw Crusher: What Is It How Does It Work? VYKIN Crushers

.jpg)

Small Jaw Crusher TAYMACHINERY

2024年8月29日 A small jaw crusher is a type of jaw crusher that is specifically designed for smallscale operations, laboratories, or where space and capacity constraints exist These crushers are suitable for crushing small amounts of hard materials into smaller, more manageable pieces Laboratories: For sample preparation and testingThe crusher mainframe has a super long jaw that offers smoother flow of materials and stronger crushing performance; the discharge opening is hydraulically adjustable, which guarantees more convenient operation 3 The crusher is equipped with an intelligent continuous feeding system that offers smoother flow of materials and more continuous Movable jaw crusherCrushing And Screening Machinery 2023年2月28日 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications These plants find application in quarrying, mining, construction, and recycling operations Stone crusher plants consist of several components, including a primary crusher, Crushing it: A Comprehensive Guide to Stone Crusher PlantsAbstract: In this article we investigate the dynamics of an inclined vibratory jaw crusher, in which oscillations of the jaws are excited only by one inertial vibration exciter, located on the upper jaw The laws of forced oscillations of the jaws are obtained The conditions for existence of the symmetrical form of forced oscillations (an ideal operating mode of the Dynamic analysis of a vibratory jaw crusher with inclined

Mobile jaw crushers for precrushing Wirtgen

Mobile jaw crushers The crushing plants of the MOBICAT series are used for the precrushing of almost all natural rock and in recycling However, the output of the MOBICAT crushing plants is determined not only by the jaw crusher alone in fact, the optimal interaction of all components plays a decisive roleThe powerful jaw crusher is capable of a variety of tasks with its large underbelt clearances, and is equipped with a hydraulic raise and lower facility on the main conveyor as standard There are a number of features to Sandvik QJ341 Mobile Jaw Crusher – World instalation of jaw crusher mechine Home Page Back Mobile Jaw Crusher is designed more reasonable and compact, including installation in broken machine bracket Shang of broken machine, 31 Jaw crusher; 32 Gyratory crusher; 33 Cone crusher 331 Compound cone crusher; Jaw crushers are heavy duty machines and hence need to instalation of jaw crusher mechine hebergementvosges2023年2月15日 a template of jaw crusher checklist 2Do the lubrication job well The lubrication of the interface between the parts of the jaw crusher is very important It can minimize the friction generated during the The Most Practical Jaw Crusher Repair and

Jaw Crusher: Range, Working Principle, Application

2022年2月22日 A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it 2020年3月19日 Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers cannot accept all material sizes Any material fed to the crusher must be presized for that particular crusher (usually 200mm or less)Selecting the right crusher for your operations QuarryThe Jaw Crusher is classified under our comprehensive Mining Crusher rangeIn China, identifying reputable mining crusher suppliers involves thorough research, checking credentials, customer reviews, and obtaining samples for quality verification Leveraging industry platforms and exhibitions also aid in connecting with reliable suppliers for Jaw Crusher MadeinChinaFind here Jaw Crusher, Heavy Duty Jaw Crusher manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Jaw Crusher, Heavy Duty Jaw Crusher across IndiaJaw Crusher Heavy Duty Jaw Crusher Latest Price,

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

The crushing performance of a jaw crusher depends on the operational sloped angle of the jaws (1) and the ir shape, the speed and the movement behavior of the fourbar linkage During one revolution of the fourbar linkage, the breaking jaw moves in vertical and k750 jaw crusher:hooklift jaw crusher The K750 combines superior crushing performance with the ability to transport with a standard hook lift truck From unloading to operating in less than 5 minutes, the K750 jaw harnesses the power of the onboard Diesel electric generator to crush 0400mm rock, concrete and brick at typically 50100tphJaw Crushers — Nordmann2019年4月25日 Jaw Crusher Product overview As a leading Jaw Crusher manufacturer in China, GATOR is committed to various jaw crushers and screening equipment design, manufacturing and sales, The jaw crushers can crush various material with compressive resistance less than 320Mpa, Feed size is from 125mm to 750mm, and with features of GATOR series JawCrusherBest JawCrusherGATOR US